When developing and monitoring the production of the Bluelavage medical irrigation system, UTK Solution relies on measurement services from Lometec.

In order to constantly keep an eye on the high quality criteria and ultimately be able to meet them, UTK relied on digitalization for this product for medical technology right from the start - including in the 3D measurement technology, for which the measurement service provider Lometec is responsible. UTK has made a name for itself in the product development and production of plastic components. With the medical product Bluelavage, the Lüdenscheid-based company has, for example, developed a sustainable, sterile single-use irrigation system that is needed every day in orthopedics and trauma surgery.

Bluelavage is made entirely of plastic

At Bluelavage No metal parts are installed, the system is made entirely of plastic and can therefore be completely disposed of as plastic waste. No batteries are required for operation either. For this, UTK was awarded the Efficiency Prize of the State of North Rhine-Westphalia in 2019. “We solve our customers’ problems and accompany them from the initial technical concepts through to the production and approval of high-precision medical products,” says Managing Director Olaf Thiessies, outlining UTK’s range of services.

UTK is also involved in a cooperation project between four companies from Lüdenscheid and Kierspe that produces antibacterial and compostable face shields:

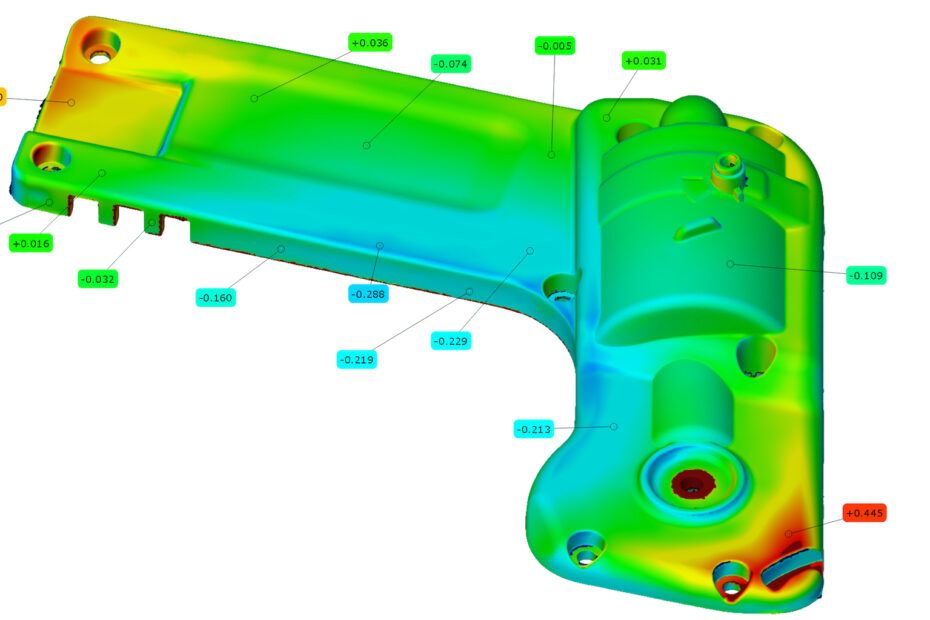

With Lometec, based in Kamen, UTK has found a partner who has various methods for 3D digitization. UTK was supported by Lometec right from the development phase of the flushing system, which consists of a total of 26 individual parts: Each individual component was developed using the 3D scanning in the Lometc laboratory measured and documented. Stripe patterns were projected onto the surfaces of the individual parts of Bluelavage and captured by two cameras using the stereo camera principle. Since the beam paths of both cameras and the projector are known in advance through appropriate calibration, 3D coordinate points can be calculated from the three different beam sections. In this way, the part geometry can be precisely recorded and documented. The result is complete measurement data without holes or erroneous points. This measurement technology is particularly suitable for complex plastic components.

You can read the entire article “Medical technology manufacturer relies on measurement service providers” on the website https://www.k-zeitung.de/medizintechnikhersteller-setzt-auf-messdienstleister/ Continue reading.